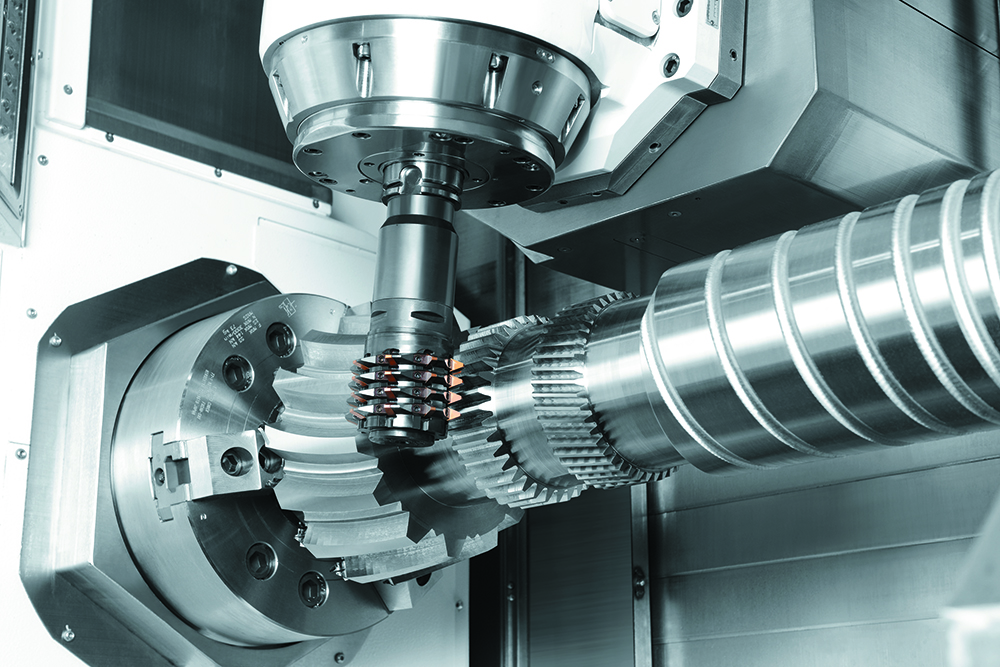

Gear Shaping is a

machinery process that applies continuous, flat-surface rotational cutting.

Shaping cutting can do an accurate cutting process that delivers a high surface

finish for internal and external teeth. The shaping can induce many gear

varieties like spurs, helical, involute splines, herringbones, and racks. Gear

shaping has the benefit of generating teeth near the shoulders, which hobbing

cannot do. Similar to gear hobbing, this gear shaping is deemed a generating

technique, but shaping depends upon the motion of a cutter scaled on a gear

blank and cutter spindle held on the fixture or an arbour on the work spindle.

Various manufacturers of gear cutting tools, those company is supplied all types of advanced machines and technology. The shaper cutters are utilised to trim the teeth of Gears. Borders of the gears are more acute. Manufacturers can supply different types of shaping like helical, chain sprockets and involute splines. They can also manufacture gear shaper cutters according to buyer-specific drawings.

Different types of shaper cutters

●

Disc type shaper

cutters:

Disk-type cutters

are prepared to cut internal and external Gears. This cutter is used to cut

serrations, splines, and many different intricate shapes. Cutters are

obtainable in tip-relief, semi-topping and protuberance. All types of coatings

are possible as per requirements.

●

Hub-type shaper

cutter:

Shank Cutters are approved for cutting

extended face width or coarse pitches. Shank cutters are fabricated with

high-grade imported raw materials.

●

Shank-type shaper

cutters:

These Shank

cutters are primarily used for engraved internal gears with small diameters.

Shank cutters are utilised for any machine's perfect or proper, fast shaping.

●

Helical Shaper

Cutters:

Helical gear

cutters are commonly employed in vehicle gearboxes. Manufacturers made these

cutters in both single and double spiral cutter forms. The manufacturers

provided these gear shaper cutters

based on their customers' drawings and specifications. Shaper cutters come in

various styles, including internal, external, hub, and shank.

●

Timing pulley

Shaper Cutters:

Timing Pulley

Cutters are obtainable in different ranges and modules. These shapers are supplied

in diverse profile features like semi-topping, tip-relief and many other forms.

Various kinds of coatings can be applied according to the customer's

specifications.

●

Chain Sprocket

Shaper Cutters:

Manufacturer and exporter of gear shaper

cutters deliver shank-type shaper cutters. All these Cutters are made in

American Standards. Aside from chain shaper cutters, manufacturers also provide

customised shaper cutters.

●

Special Profile

Shaper Cutters:

Manufacturers of

gear shaper cutters can supply special Profile Cutters. If clients provide

particular conditions and drawings, buyers can also send complete details to

make with.

●

Skiving Shaper

Cutter:

These shaper cutters are available in both regular and non-standard profiles and every manufacturer can offer custom shaper cutters in any kind of material and size range.

Shaper cutters

are gears with alleviated cutting edges that allow clearance during the cutting

operation. Special features include chamfering, protuberance, topping, full

radius, and so on. It can be incorporated into the cutter's tooth form. The

requirements of the work item will determine these specific qualities.

0 comments: